Latest News at HydraForce

Challenge Accepted: HydraForce takes on Agritechnica visitors’ toughest machine challenges at Stand B12 in Hall 16

iVT visitors invited to take the “HF Challenge” at booth 1013 to earn a prize

HydraForce becomes 2023 Winner of the Best and Brightest Companies to Work For® Competition, for the sixth year.

The iVT Expo Conference returns at the end of this month in Cologne, Germany; with three highly anticipated subjects on the agenda

HydraForce Launches HF-Impulse™ 2.0 Configuration and Programming Software Christina Alvarez Makes programming HydraForce electronic controllers easy for beginners Features robust capabilities

HydraForce Debuts New Software at CONEXPO-CON/AGG and IFPE 2023 HF Impulse 2.0 and i-Design™ updates will be showcased at booth S80207 HydraForce, a leading manufacturer of hydraulic valves and

Bosch Rexroth completes HydraForce acquisition to enhance global hydraulics offering Acquisition completed after approval by antitrust authorities After receiving approval from the antitrust

HydraForce has partnered with Harper Adams University, to become part of HandsFree Hectare Autonomous Farming Project, which promises to open doors into a new area of the agricultural industry.

HydraForce's Global Systems Integrator, Dantal Hydraulics, won Best Supplier in December for JCB.

HydraForce Partners with Tan Delta Systems HydraForce Partners with Tan Delta Systems to provide real-time data to improve machine performance in the field. HydraForce, global manufacturer of

HydraForce signs acquisition agreement with Bosch Rexroth Two complementary players unite to offer comprehensive product portfolio for mobile and industrial applications: Joint portfolio broadens

HydraForce and AEM hosted US Rep Brad Schneider HydraForce and The Association of Equipment Manufacturers (AEM hosted United States Representative Brad Schneider (D-IL) for an "I Make

HydraForce Apprentice wins the Made in the Midlands Award 2022 Megan Tolley HydraForce is delighted to announce that former apprentice, Owen Miles, has won the Made in the Midland’s Apprentice of

HydraForce Ltd welcomes U.S. Embassy to Birmingham UK Megan Tolley HydraForce Limited was delighted to host a visit from the U.S. Embassy last month, to review how recent changes in working life

How IoT Improves Telematics in Mobile Equipment IoT usage in fleet management is on the rise. Buyers and users of mobile equipment are increasingly interested in learning how adding remote access

HydraForce Ltd Apprentice shortlisted for Made in the Midlands Award 2022 Megan Tolley HydraForce Hydraulics Ltd, Birmingham UK, is delighted to announce that they have been shortlisted for the

Congratulating our top distributors of 2021! We thank them, and all our distributor partners, for the vital role they play in our business and in applying our technology to improve the hydraulic

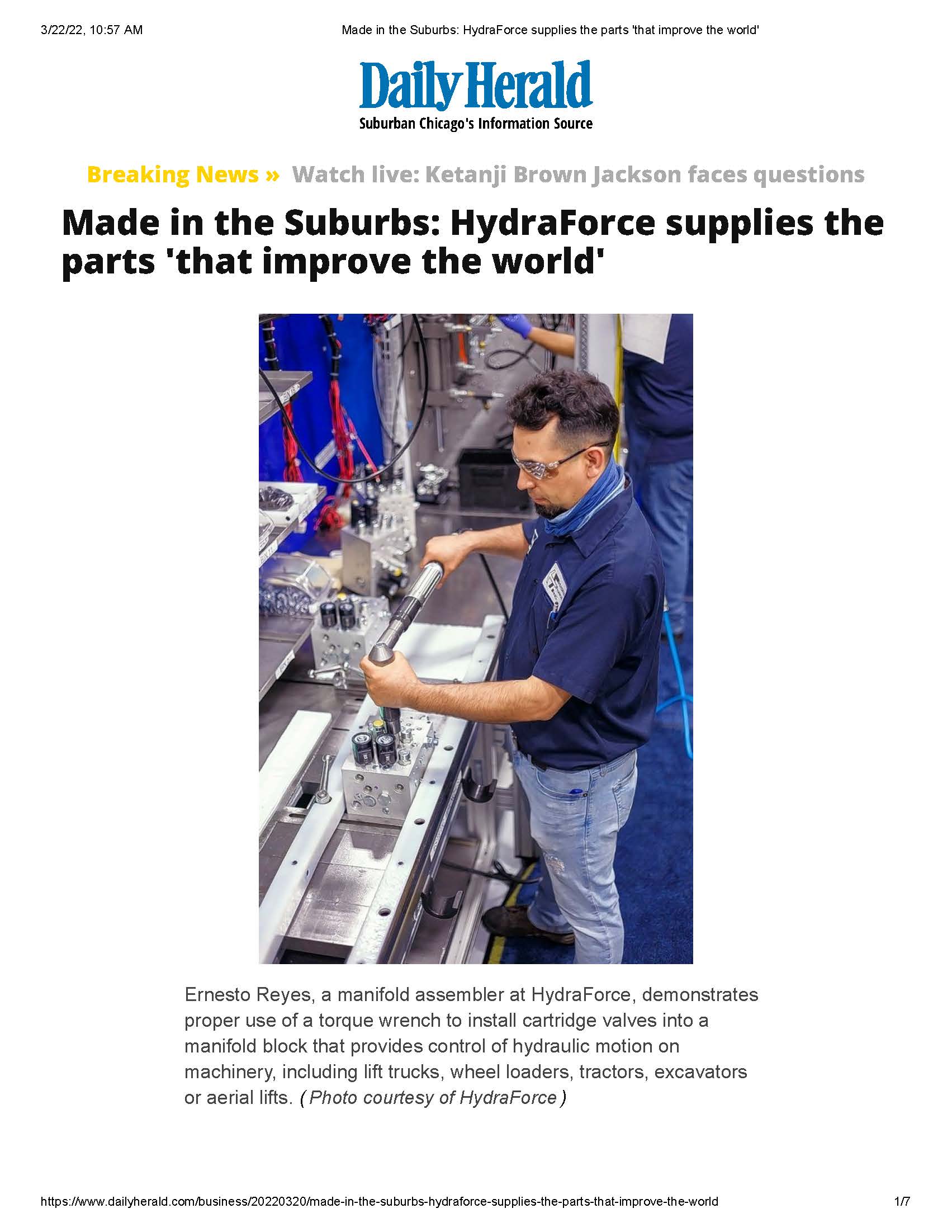

HydraForce was featured in the Daily Herald's "Made in the Suburbs" column. The question and answer format gives readers some insight on our business, mission/vision, and outlook. The

Calibration Manager Vasilios Kokkinos, Quality Auditor Gaby Avellan, and North American Quality Manager Jomy Joseph, display the new ISO 9001 certificate which is on display in the HydraForce

LEAP Award Each year, Design World magazine presents LEAP (Leadership in Engineering Achievement Program) Awards to celebrate the most innovative and forward-thinking products serving the design

Electronic control units (ECUs) became a part of the HydraForce lineup of products more than ten years ago when mobile equipment customers asked for "one-stop shopping" for electrohydraulic

How Using IoT for Fleet Management Saves Time and Reduces Costs The Internet of Things (IoT) can drive strategic change for any business with fleet vehicles or machines as it connects physical

In November, a group of 15 HydraForce employees involved in testing our products completed the Fundamentals of Pneumatic Testing course conducted by ATEQ, the manufacturer of the testing

As the hydraulics industry migrates toward greater implementation of electronics, HydraForce is moving along with it. Our application engineering team recently completed certification by the

IoT Fleet Management System Checklist for Off-Road Vehicles and Equipment Fleet management systems allow you to remotely maintain, diagnose, and service your fleet of off-road vehicles. The

Triple Award Winners HydraForce Ltd triumph at the Greater Birmingham Apprentice Awards 2021 Megan Tolley Photograph Credit: BirminghamLive & Reach plc. HydraForce Hydraulics Ltd is delighted

Modern fleet management solutions like Epec’s GatE and GlobE tools and cloud-based services use IoT technologies to manage the operation of connected vehicles. The benefits include higher

Last month, Messick Equipment did a test demonstration and video review of our prototype Skid Steer Loader control system.

HydraForce Ltd shortlisted for Greater Birmingham Apprenticeship Awards 2021 Megan Tolley HydraForce Ltd is delighted to reveal that they have been shortlisted for both Large Employer of the Year

This video shows Messick demonstrating the many unique hydraulic functions of this machine, including "return to dig," bucket shake, soft ride, float, self-leveling, telematics and a beginner

HydraForce is proud to announce that Jim Brizzolara and Dick Fontecchio were BOTH inducted in the Fluid Power Hall of Fame on Wednesday, October 6 in Reno, NV. Jim received a legacy award and Dick

HydraForce Hydraulics Ltd, based in Birmingham’s Advanced Manufacturing Hub, has appointed Jon Bradley as its new Managing Director from 1 June 2021.

Congratulating our top distributors of 2020! We thank them, and all our distributor partners, for the vital role they play in our business and in applying our technology to improve the hydraulic

HydraForce Hydraulics Ltd in Birmingham UK, has been shortlisted for both the Apprentice of the Year and Export Award at the Made in the Midlands Awards 2021.

HydraForce COVID-19 Update - January 2021 At HydraForce we continue to take steps to help reduce the spread of COVID-19, whilst protecting the health and safety of our customers and employees.

HydraForce COVID-19 Update - November 2020 Mike Terzich At HydraForce we continue to take steps to help reduce the spread of COVID-19, whilst protecting the health and safety of our customers and

HydraForce offers engineering internships. In 2020, the year’s group included 11 students from 8 colleges and universities, from Tennessee to our home state of Illinois.

New General Manager appointed for North America HydraForce is pleased to announce the appointment of Dan Holtzinger as General Manager of our North American facilities. Dan will begin his new

HydraForce Ltd shortlisted for Birmingham Apprenticeship Awards 2020 Megan Tolley HydraForce Ltd, based in Birmingham UK, has been nominated for Ladder for Greater Birmingham’s Large Employer of

Six Sigma at HydraForce Six Sigma has been a universally accepted problem-solving methodology adopted throughout global manufacturing and commerce since the mid 1980’s. It focuses on applying